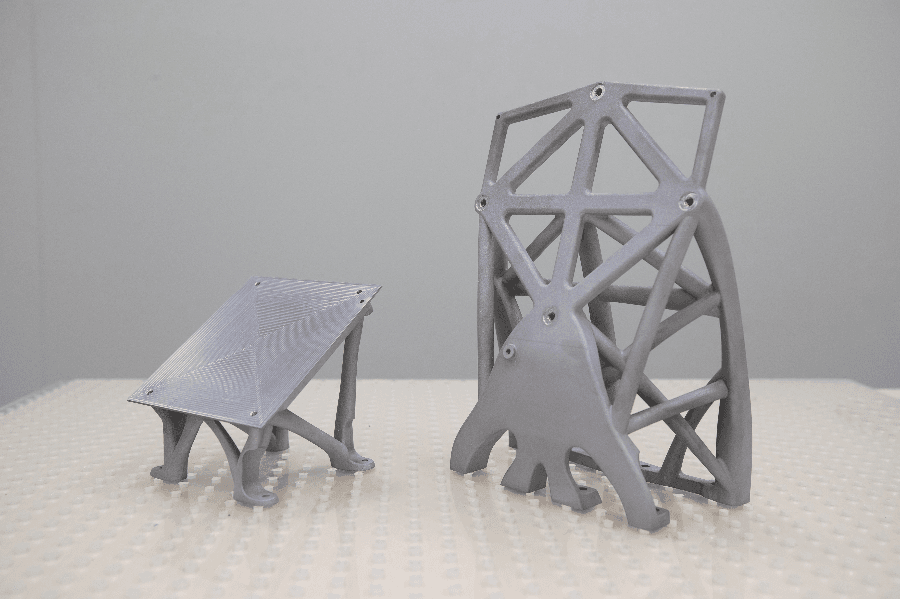

Turkish Aerospace (TUSAŞ) used Additive Manufacturing Technology for the first time on the satellite's structural component. A three-dimensional printer, analysis, qualification and manufacturing processes, along with proficiency testing, has been completed.

TUSAS announced from its Twitter account, "We achieved production and qualification of satellite structures with 3D printers based on Additive Manufacturing Technology. We are proud of adding a new production model to our structure in our indigenous aviation and space ecosystem."

According to TUSAS Press Release, three-dimensional printing uses melting metal, ceramic and polymer components layer by layer with the Additive Manufacturing Method. The method will be used at the machining of mission-critical space structural parts.

The new advanced technology will provide a 30 % weight gain thanks to advanced structural optimization software in the developed parts. It is aimed to use the features, which have completed many space proficiency tests at the Space Systems Integration and Test Centre (Uzay

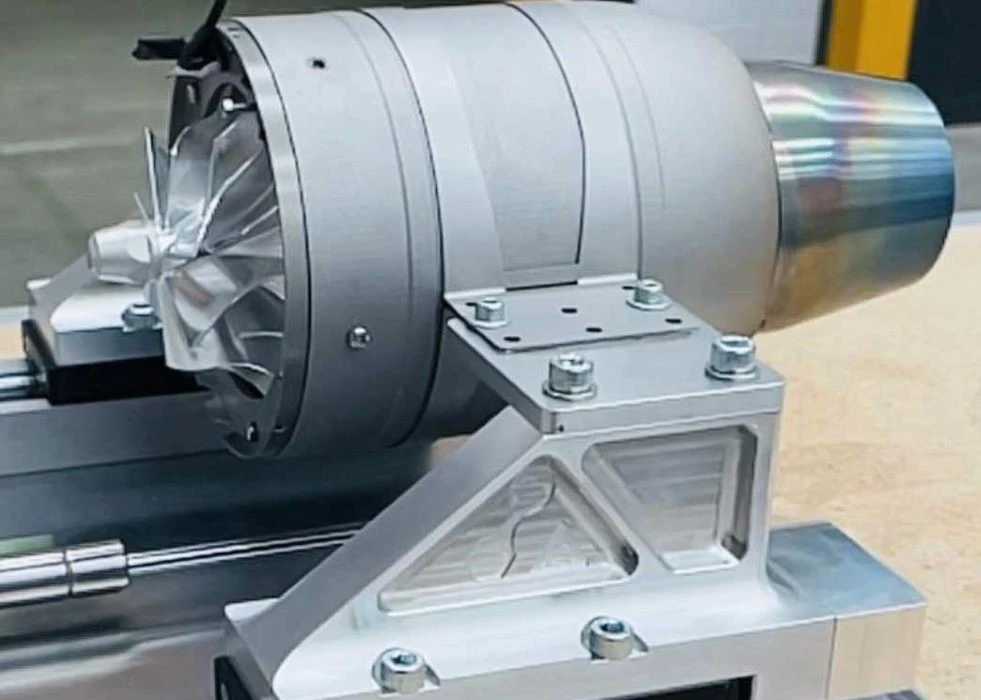

Sistemleri Entegrasyon ve Test Merkezi/ USET) within the body of TUSAŞ, in high

technology communication satellites.

The Additive Manufacturing Technology Centre is established in TUSAŞ. The production will begin from the raw material stage, and Turkey's largest-sized titanium and aluminium alloy strategic

aviation and space components will be manufactured.